- Home

- About

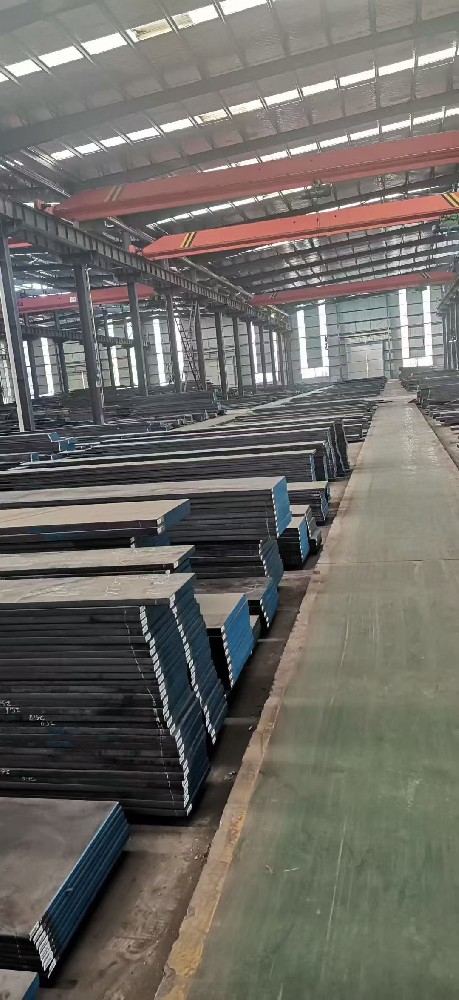

Dedicated production and design and commitment to quality, we are your trusted source for high-performance Die Steel. Our high performance products, custom solutions, global reach, and dedication to innovation set us apart in the industry. Explore our range of precision-engineered screens and experience the Minghang difference today.

- Products

- News

了解最新公司动态及行业资讯

- Industries

服务创造价值、存在造就未来

Wedge wire screen products are playing positive and crucial roles in different industries and in many applications within each industry. They will help to increase filtering efficiency, improve product quality, protect environments and guard people's health.

- Contact

能为您服务是我们的荣幸

能为您服务是我们的荣幸No matter you want to inquiry wedge wire prices, customize filtration solutions or solve current problems, just feel free to contact us. Let's boost your efficiency and quality together!